FAQ Frequently Asked Questions

Compressed earth blocks require a clay based soil, that is, a soil that contains enough clay to bind the block together after it’s compressed in the machine. The amount of clay can vary, from 15% to as high as 40% and the type of clay can also vary. There are three main types of clay, Kaolinite being the most common. It’s important to know how much the clay in the soil to be used will expand when wet and there are simple tests to measure this.

We can provide you with simple field tests that help you evaluate the soil you have and what components it contains. We also have a simple and portable lab kit for soil testing in the field. You can also submit soil samples to laboratories all over the world that can analyze your soil and determine its characteristics and ingredients. We also on site training and work with you to determine the best soil to use, the best way to make blocks and how to build with the blocks.

Because the blocks contain some cement, they will take 28 days to cure completely. But, if cured properly the blocks can be used for construction after only seven days.

Cement products require moisture and heat to cure properly. So the best method for curing compressed earth blocks is to stack the blocks on a pallet in the sun, wet them down and cover them with black plastic. The trapped moisture under the plastic creates a high humidity environment and the plastic in the sun insures plenty of heat. Blocks cured in this fashion are strong and can be used in a week’s time.

The amount of cement can vary, usually due to more or less clay. The higher the clay content of the soil, the more cement is needed. Typically it takes 6 to 8% cement by weight, a 100 kilo mix would require 6 to 8 kilos of cement, the rest is soil.

Mechanical mixers produce a very homogenous mixture, reduce labor costs and simplify the block making process. But they add to the initial cost of equipment so usually the decision to purchase a mixer is based on the buyer’s budget. If a mixer is purchased, it is often accompanied by a conveyor to transport the mixed material to the hopper of the block press. A variety of mixers are available, based on the volume of mix required and the style of mixer, pan verses auger.

There are many aspects to the cost of a house so it’s a difficult question to answer in a general way. For very basic house designs, our experience has been that compressed earth block houses are less expensive, from 5 to 40% less, when compared to other building methods. The reason is due to the lower cost of building material, especially if the dirt on site can be used to make blocks, the lower cost in labor, many earth block walls are built with unskilled labor, and the speed of construction which is typically faster than other building methods.

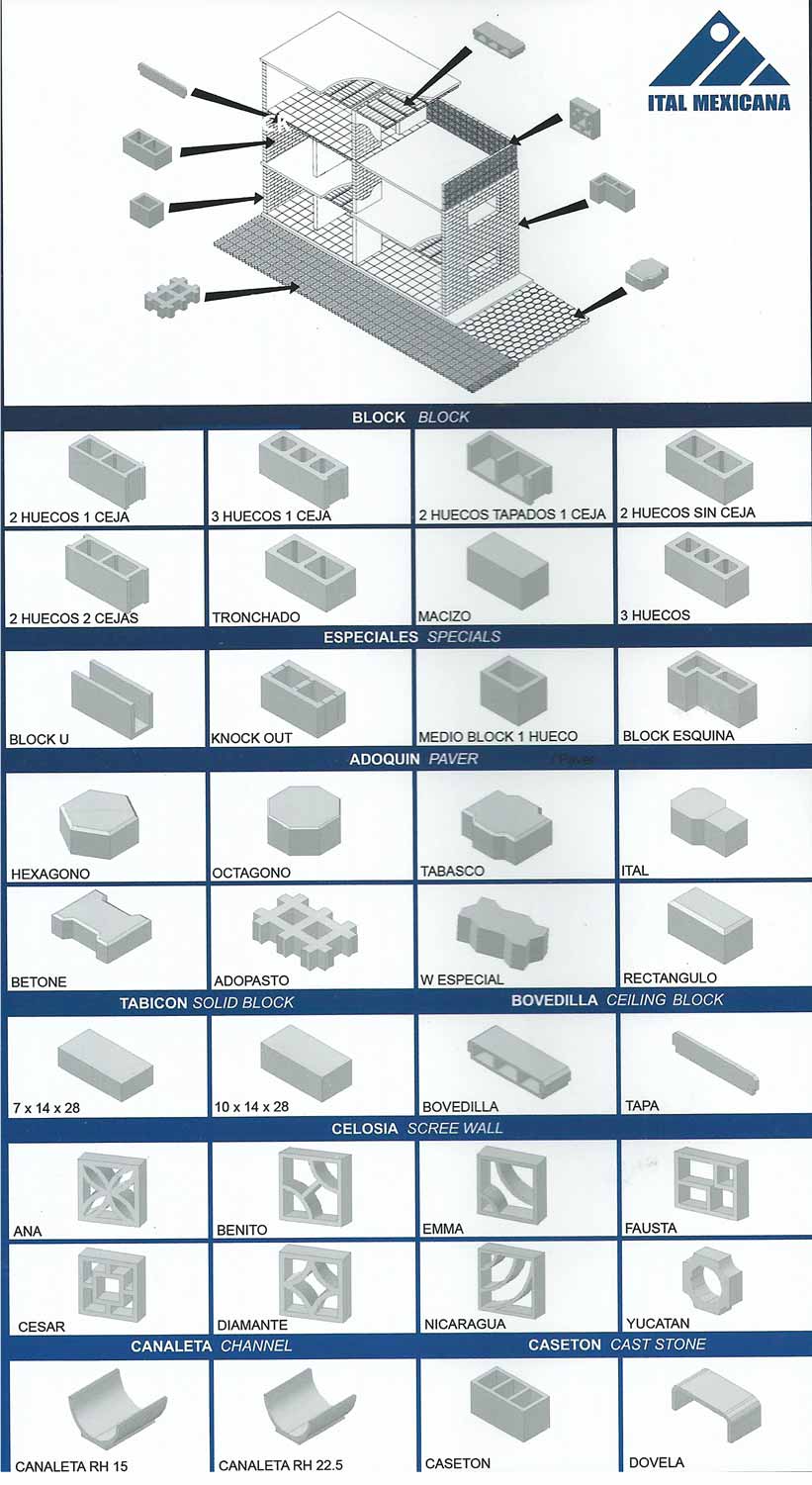

Depending on the type of block, interlocking verses standard, Ital offers a wide variety of block designs and dimensions. Our Tadpress machine even allows for custom block designs. Our concrete block machines produce a huge selection of block designs (see below).